No-Fli & The University of Sheffield, UK

Replacement of Pest control fly killer contract in 13 university of Sheffield buildings

No-Fli working with the University of Sheffield were chosen to replace a national provider of pest control and standardise 55 fly killers in 13 university buildings around the City of Sheffield.

The university management based their decision on the following factors:

- Sustainability – No-Fli made in Yorkshire offered a UK made product that reduced the environmental foot print in travel miles, a lifetime guarantee over a 3 year guarantee and 90% less material than the units used by pest control.

- Cost – A massive saving over expensive pest control service contract costs, with a commitment from No-Fli to replace 55 out of service fly killers free of charge and fitted free.

- Non-Contracted Service – No-Fli offered a non-contract commitment to the university over a signed long agreement from the pest control provider.

- Standardisation of product – No-Fli replaced 55 fly killers and the fly killers replaced, were made up of over 10 different models which either needed different types of UV lamps, glueboards and some were dirty zappers which had caused damage to the walls. By switching to No-Fli all fly killers use the same lamps and glueboards which is very easy to manage.

University of Sheffield locations

The evaluation and fittings took place within all 14 buildings which contained 17, different sized food outlets. No-Fli found that these old, pest control maintained fly killers had not been serviced for several months. Meaning, each location had between 1 and 7 fly killers to replace.

These included Krebs café, café 1828, courtyard café, the view deli, inox dine, oasis café, solly st café, the diamond kitchen, north campus café, Jessop café, information commons café, Arts tower café, Bartolome café, the edge café bar, the edge kitchen, grill and go, the university arms.

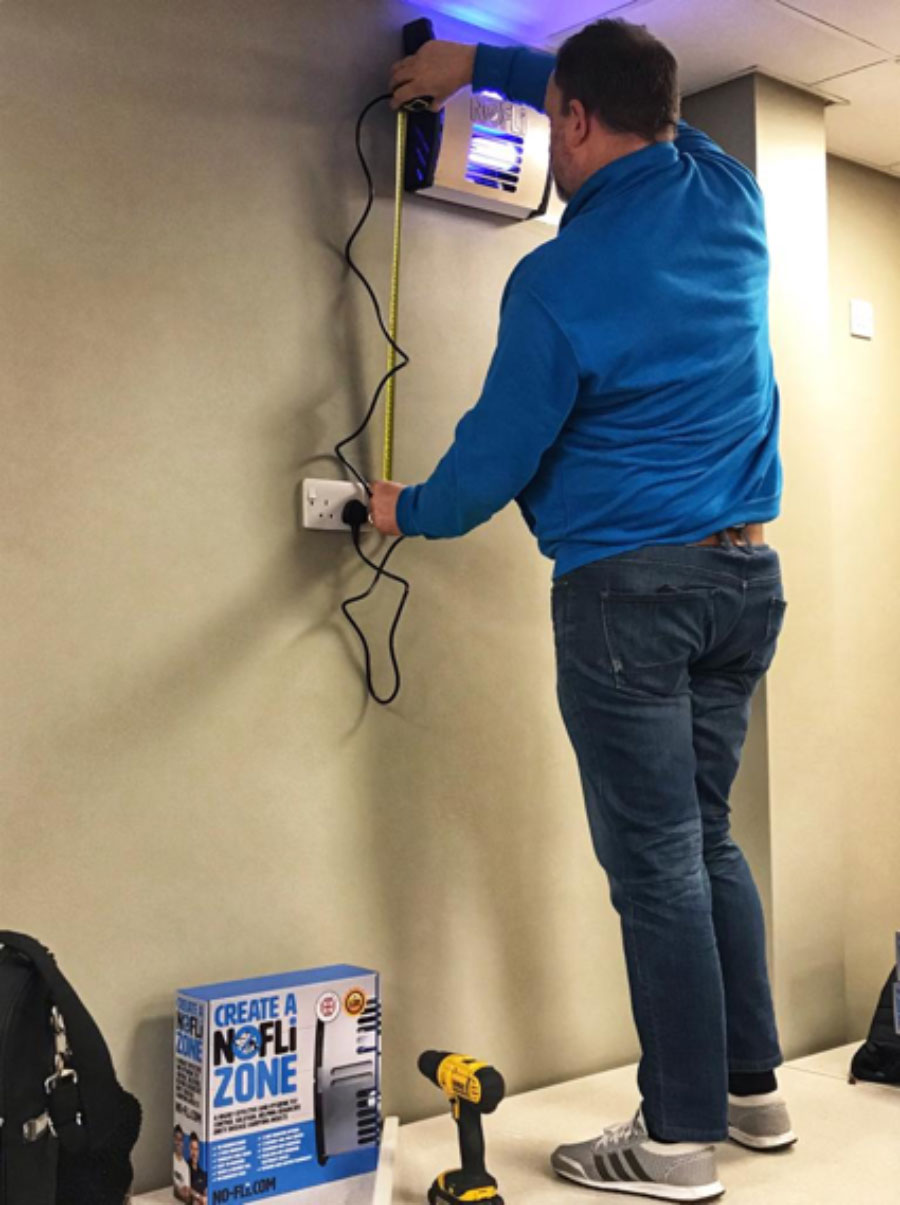

53 No-Fli Fly Killers – installed in only 2 days!

Once each location had been evaluated. No-Fli instructed a team of 4 people to fit the new No-Fli fly killers. This took only two days to complete and included the hard wiring of 5 fly killers.

Once installation was complete, No-Fli met with each person responsible to ensure the maintenance instructions were understood and agreed.

Zappers Replaced

10% of the fly killers replaced were zapper products and not fit for purpose. They had major flaws creating serious issues in health and hygiene.

- Dead Flies had been blown out into the surrounding area where food was being prepared.

- Fly debris stuck to the walls creating a totally unhygienic surface.

- UV staining on the walls due to no protection from the UV Light.

- Dead Flies stuck to the high voltage grid causing a fire hazard.

- Multiple units that had faulty lamps.

- A shallow insect collection tray with insufficient height and causing insects to be blown potentially into the food chain.

- One unit with no collection tray with dead insects dropping out.

- Dead Flies and Fly body parts which had hit the high voltage grid and landed outside of the insect killer and potentially into food preparation areas.

- Large build up of dead flies in the collection trays.

Image of large heavy industrial zapper replaced by No-Fli

Dead insect fragment from zapper on food prep surface

All the staff commented on how much more stylish was compared to the models replaced and were amazed at how easy to clean each unit was. While instructing on how to change the boards and lamps each person changed the board in less than 5 seconds!!!

The Benefits

There were numerous benefits of fitting a no-fli insect management system into the professional kitchen areas of all the university locations. Obviously the aesthetic looks of the product mean that it is a discreet flykiller. This means that flies cannot be seen on the product. However, all though aesthetics are important the major improvements noted by the management included:

A 100% cleaner operation was noted over the previous pest control operation. Zappers installed had shown insects to be falling out onto the floor. Dirty insect particles were splattered onto the back wall and underneath the trays. The glueboards used had not been changed in 6 months!

Using No-Fli also has helped maintain the product and ensures all boards and UV lamps are changed as directed.

The “zappers” had caused UV staining on the back walls and as using no-fli ensures that no – UV light escapes onto the walls this was completely solved.

The management and staff were delighted with the simple maintenance of simply removing the board from the bottom of the no-fli unit and this has been met with much enthusiasm.

Another key driver was the price of using the No-Fli system over a pest control company. Obviously, there is huge cost when pest control companies have to constantly send staff out in vans with both fuel and time. No-Fli eliminates both of these expensive costs without compromising quality. In some instances companies have saved over £8250 on the actual units and fitting and over £4000 per year in service costs! Over a 3 year contract this is a massive cost saving for any company!

Other pest control companies tendering for the fly control requirements of the University were wanting to sign the University into 3 years contracts. No-Fli don’t work in this fashion – no contracts or leases. No-Fli provide a 12 month delivery only service with monthly reminders and a life time warranty.

Can No-Fli Help You?

From 1 – 1000 sites. No-Fli would like to hear from any business interested in a quality UK made fly killer. No-Fli will help your premises be the most hygienic and sustainable with a unique and low cost service management system. Fitted FREE, nationwide – hello@no-fli.com.